Precision CNC machining is one of the many custom manufacturing services offered at our CNC machine shop in Southern California. To provide CNC machined parts with precision and tight tolerances that many industries require, we offer the machining experience from our staff and the best in CNC machines and technology. With over 200 combined years of experience machining, we offer CNC machining services for a variety of metals and shapes. Our CNC mills are programmed utilizing the latest in numerically controlled programming for Surfware. Surfcam, by Surfware, enables us to machine parts in an extremely efficient manner to each of our customer's requirements.

Precision CNC machining is one of the many custom manufacturing services offered at our CNC machine shop in Southern California. To provide CNC machined parts with precision and tight tolerances that many industries require, we offer the machining experience from our staff and the best in CNC machines and technology. With over 200 combined years of experience machining, we offer CNC machining services for a variety of metals and shapes. Our CNC mills are programmed utilizing the latest in numerically controlled programming for Surfware. Surfcam, by Surfware, enables us to machine parts in an extremely efficient manner to each of our customer's requirements.

CNC Machinery Utilized in Our CNC Machine Shop

If you’re looking for a quality precision CNC machine shop in the Southern California area, our precision CNC machining services and 4 axis machining is handled in-house at our Anaheim location. We utilize the following state of the art equipment for our CNC precision machining and milling:

- Hurco VMX50 Vertical Mill with 4th Axis capability and 50" by 26" by 24" envelope

- Hurco VMX42 Vertical Mill with 4th Axis capability and 42" by 24" by 24" envelope

- Hurco VM3 Vertical Mill with an envelope of 50" by 18" by 18"

- Hurco TM10 Lathe with a 10" chuck

- Whacheon Lathe with 12" chuck

- FEMCO Durga with a 10" chuck

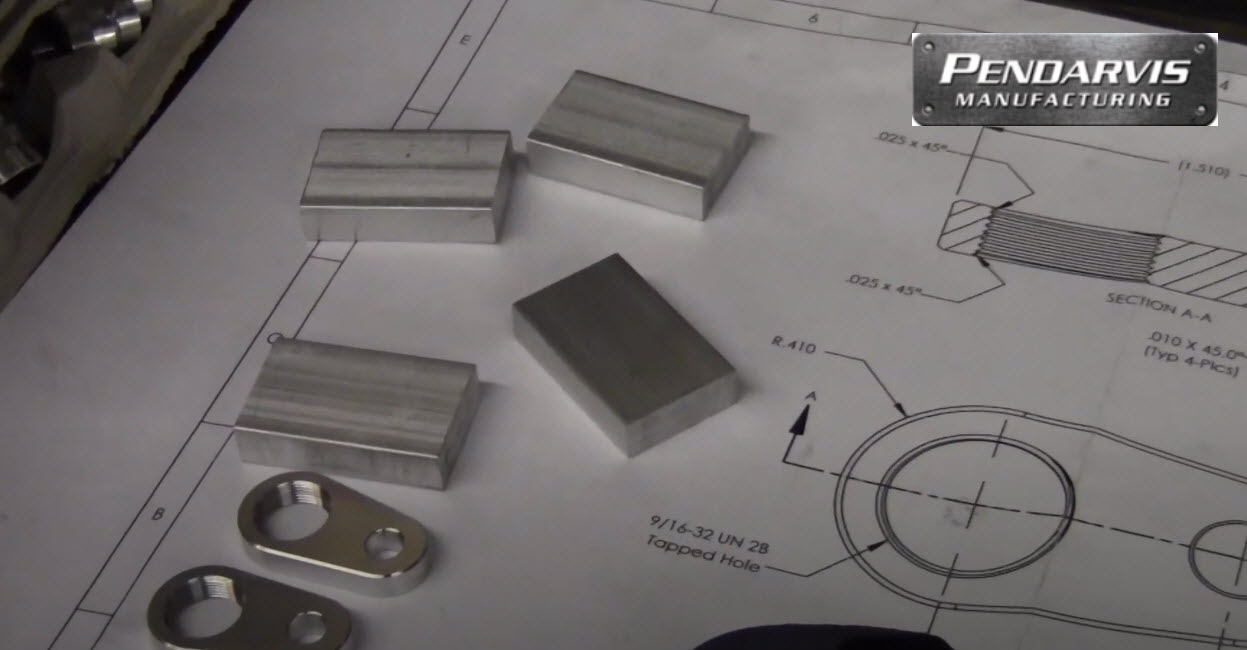

Additionally, we follow CAD and CAM drawings and specifications, meaning we can fulfill the requirements of our client's. Whether a low or high volume order of intricate machined parts, Pen Manufacturing has the tools and experience combined to create accurately machined parts to your needs.

What is CNC Machining?

Computer Numerically Controlled or precision CNC machining was initially developed over 50 years ago by a group of machine tool builders involving machine work that needed to be completed for the U.S. Air Force. From its early inception, precision CNC machining was designed to consistently replicate and reproduce parts requiring multiple complex machining steps, eliminating the part-to-part variations of the human machinist/operator. The successful result of a CNC precision machining and 4 axis machining process relies on experienced CNC machining specialists to program the CNC procedure properly, since the entire process, once started, is automated.

Computer Numerically Controlled or precision CNC machining was initially developed over 50 years ago by a group of machine tool builders involving machine work that needed to be completed for the U.S. Air Force. From its early inception, precision CNC machining was designed to consistently replicate and reproduce parts requiring multiple complex machining steps, eliminating the part-to-part variations of the human machinist/operator. The successful result of a CNC precision machining and 4 axis machining process relies on experienced CNC machining specialists to program the CNC procedure properly, since the entire process, once started, is automated.

CNC Machining Advantages

CNC machining offers the following advantages:

CNC machining offers the following advantages:

- Highly precise production parts- extremely small tolerance variations, with the resulting components being virtually the same in all aspects.

- Low labor requirements and costs - one experienced precision machining specialist, using a CNC machine, can perform the jobs of several people. Fewer errors on the finished component mean lower cost to produce parts.

- Increased productivity - once the initial setup is done, precision CNC machining can literally continue 24 hours a day (limited only by cutter wear if applicable and the on-hand inventory of the raw material being used).

- Safer production - the precision machining specialist monitors the process, but is not involved in performing the machining steps of the process, leading to a safer manufacturing environment. The precision CNC operator oversees the automated process and can stop the CNC machining, if a correction is required.

Along with 4 axis machining, precision CNC machining and custom metal fabrications services, additional in-house capabilities at the Pen CNC machine shop in Southern California include but not limited to:

- Plumbing

- Hydraulic assembly

- Electrical wiring

- Glass-beading

- Painting

- Delivery to the customer's site

PRECISION CNC SMALL PARTS